Attention to Detail in the Production of Glass Cork Bottles includes several key elements. Firstly, the selection of high-quality raw materials, including glass and cork, is crucial. Careful inspection and testing of these materials ensure that they meet the required standards for strength, durability, and safety.

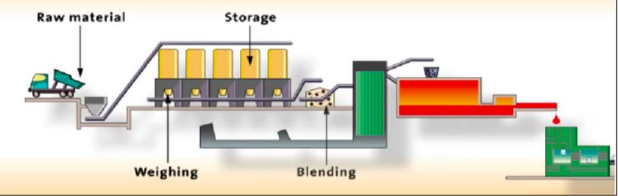

Secondly, the manufacturing process must be closely monitored to ensure that each stage is executed precisely. This requires the use of advanced machinery and technology, as well as skilled workers who are trained to maintain the highest standards of quality and efficiency.

Thirdly, attention to detail extends to the design and shape of the glass cork bottle. The bottle must be attractive and functional, with a shape that is not only aesthetically pleasing but also optimized for storage and transportation.

Finally, quality control and testing procedures are in place to ensure that each glass cork bottle is free from defects, such as chips, cracks, or leaks. This involves a thorough inspection of the finished product to ensure that it meets the required standards for performance and durability.

Overall, the attention to detail in the production of glass cork bottles is essential to creating a high-quality, safe, and aesthetically pleasing product that meets the needs of consumers and businesses alike.