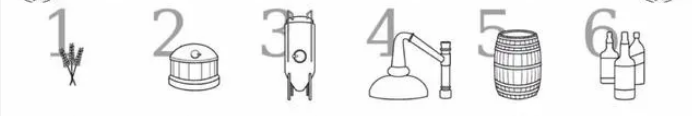

Whiskey making is an art that combines tradition with science. While different types of whiskey can have unique brewing processes, the fundamental steps remain consistent. All whiskeys start with malted barley, which serves as a natural saccharifying agent to convert raw starches into sugars. This process ultimately leads to the creation of the rich, amber liquid that we know as whiskey.

Let’s take a closer look at the whiskey brewing process, which can generally be broken down into the following stages:

1. Soaking

The journey begins by soaking barley in water to promote germination. While biological enzymes can be used as saccharifying agents, malted barley remains the mainstream choice. Modern breweries often utilize professional germination machines that resemble giant drum washing machines to better control temperature and humidity.

2. Drying

Once the barley germinates, it transforms into “green malt.” This malt is then dried at 60-70 degrees Celsius to halt germination while retaining essential amylase enzymes for saccharification. In Scotland, peat is traditionally used as fuel, imparting a distinct peat flavor to the whiskey.

3. Grinding Raw Materials

Next, the dried barley is ground to release starch granules, facilitating saccharification. Raw materials can include pure malt (germinated barley) or a blend of grains like corn, wheat, and unmalted barley, which together account for approximately 80% of the total ingredients.

4. Saccharification

Ground raw materials are combined with hot water to create a paste, known as the mash. Saccharification occurs at 60-65 degrees Celsius, and the quality of water used—often referred to as “mother water”—is crucial as it significantly influences the whiskey’s character.

5. Fermentation

After saccharification, the mash is cooled to 20-30 degrees Celsius, and yeast is added to initiate fermentation. Within about three days, a low-alcohol “wash” of approximately 7% alcohol by volume is produced.

6. Distillation

The wash is then distilled, taking advantage of the fact that the boiling point of alcohol (approximately 80 degrees Celsius) is lower than that of water. This allows alcohol and aromatic components to vaporize and condense into liquid form. Distillation typically occurs 2-3 times or continuously, producing a new spirit with roughly 70% alcohol content.

7. Aging and Maturation

The distilled spirit is transferred into oak barrels, where it must be diluted with water to about 65% alcohol. The aging process is essential, as oak barrels absorb impurities and impart color and flavor compounds. This micro-oxygen environment allows for continued oxidation, enriching the whiskey’s character over time.

8. Blending and Bottling

Different barrels yield distinct flavor profiles due to variations in aging conditions. To achieve a consistent product, whiskey from various barrels (and sometimes different years) is blended. The final product is typically diluted to above 40% alcohol content, ensuring it meets quality standards. Some distilleries may also produce single barrel whiskeys that are bottled without blending.

At Valiant Glass, we specialize in providing high-quality glass packaging solutions tailored to the spirits industry, including Whiskey Bottles, Vodka Bottles, Rum Bottles, and Gin Bottles. Our commitment to sustainability ensures that your packaging not only looks stunning but is also environmentally friendly.

For more information on our Spirits Bottles and other glass container solutions, feel free to contact us. Together, we can create innovative packaging that reflects your brand’s identity and stands out in the marketplace.

If you’re looking for more knowledge of glass bottles, check out the following articles:

– Top 4 Drinking Glass Manufacturers in the U.S

– Top 10 Glass Bottle Manufacturing Companies in India(Latest Updates)

– Top 10 Glass Bottle Manufacturers In The USA

– Why Choose Apple Juice in Small Glass Bottles? A Flavorful Experience

Consult Your Valiant Glass Bottles & Packaging Experts

We help you avoid the pitfalls to deliver the quality and value your glass bottle and jar need, on-time and on-budget.