In people’s minds, glass is a fragile and transparent material, and because the sharp fragments can easily hurt people, it is not very safe. However, with the development of science and technology, people can not only give full play to the natural advantages of glass, but also adjust its performance to make up for its shortcomings. Let’s take a look at how to make ordinary glass thermos bottles and how to frost the surface of glass bottles.

How to make ordinary glass thermos bottle

The glass bottle production process mainly includes:

Raw material preprocessing. Crush the bulk raw materials (quartz sand, soda ash, limestone, feldspar, etc.) to dry the wet raw materials, and remove iron from the iron-containing raw materials to ensure the quality of the glass.

Batch preparation.

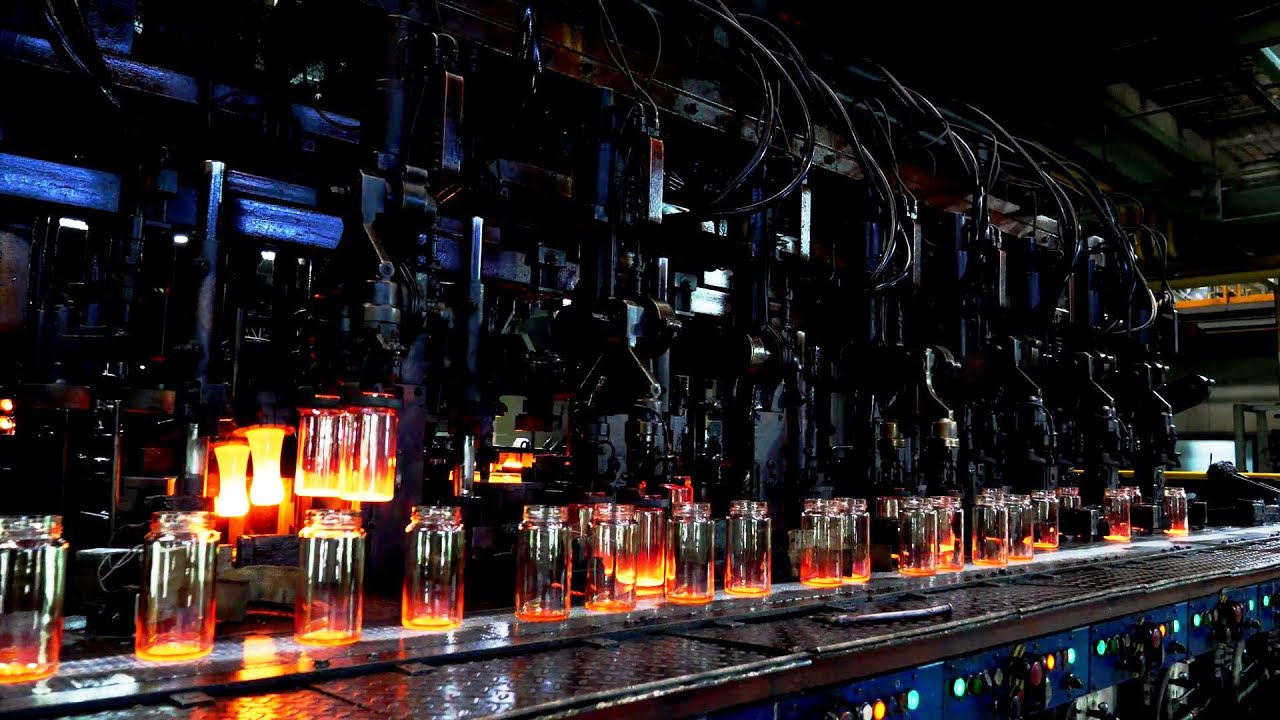

Melting. The glass batch materials are heated to high temperature (1550~1600 degrees) in a pool kiln or furnace to form uniform, bubble-free liquid glass that meets the molding requirements.

forming. Put the liquid glass into the mold to make glass products of the required shape, such as flat plates, various utensils, etc.

heat treatment. Through annealing, quenching and other processes, the stress, phase separation or crystallization inside the glass is cleaned or generated, and the structural state of the glass is changed.Glass bottle surface frosting processing method

The process of producing frosted glass using chemical methods is:

Cleaning and drying: First, clean the flat glass used to produce frosted glass with water to remove dust and stains, and then dry it;

Hoisting: Put the cleaned and dried flat glass into the lifting frame. The part of the hanging frame that is in contact with the glass is padded with toothed rubber brackets. The glass is discharged vertically, with a certain distance between the glass and the glass. Use a crane to lift it. rise;

Corrosion: Use a crane to immerse the flat glass together with the lifting frame into the corrosion box. Use conventional corrosive liquid to immerse the glass. The corrosion time is 5-10 minutes. After lifting with a crane, drain off the remaining liquid;

Softening: After draining off the residual liquid, a layer of residue is attached to the frosted glass, put it into a softening box to soften, immerse the glass with conventional softening liquid, soften for 1-2 minutes, and remove the residue;

Cleaning: Due to corrosion and softening, the frosted glass body contains many chemical substances, so it must be cleaned. Put the frosted glass on the slide of the washing machine. The slide drives the frosted glass into the cleaning machine. The cleaning machine sprays clean water while rotating the brush. , when the frosted glass is taken out of the cleaning machine by the cleaning machine slide, the cleaning of the frosted glass ends;

The cleaned frosted glass is put into the drying room to dry, and it becomes single-sided or double-sided frosted glass.Related concepts

Glass

Glass is an amorphous inorganic non-metallic material. It is generally made from a variety of inorganic minerals (such as quartz sand, borax, boric acid, barite, barium carbonate, limestone, feldspar, soda ash, etc.) as the main raw materials, and a small amount of auxiliary raw materials are added. of. Its main components are silica and other oxides. The chemical composition of ordinary glass is Na2SiO3, CaSiO3, SiO2 or Na2O·CaO·6SiO2, etc. The main component is silicate double salt, which is an amorphous solid with an irregular structure. It is widely used in buildings to isolate wind and light, and is a mixture. There are also colored glass mixed with certain metal oxides or salts to show color, and tempered glass made by physical or chemical methods.

Frosted

Frosting is a process that makes an object with a smooth surface non-smooth so that light irradiates the surface to form a diffuse reflection. Frosting treatment in chemistry is to grind glass mechanically or manually with emery, silica sand, pomegranate powder and other abrasives to make a uniform and rough surface. Hydrofluoric acid solution can also be used to process the surface of glass and other objects. The resulting The product becomes frosted glass. Scrub in beauty is a method of exfoliating dead skin cells. Although the effect is good, it cannot be used frequently. It should be determined according to your own skin condition. Excessive scrubbing will cause the new cells on the surface to be “scrubbed” to death before forming a self-protective film. External bacteria and other pathogens will take advantage of this, making the delicate skin more vulnerable to external damage such as ultraviolet rays. .